Patented Sustainable Robotics Unlocking Human Potential in Construction

Why We Exist

General Systems, seeks to introduce new AI led smart machines to automate labour dependent, highly manual activities. We believe that sustainable and affordable infrastructure development is key to building inclusive societies, and are committed to addressing construction sector’s challenges around low workforce productivity, high worker injuries, high material wastage and enabling the Industry's business sustainability.

Industry Backers

Incubators & Accelerators

Milestones

Top 10 Construction Tech Startups in APAC [Construction Tech Magazine 2021 Award]

Deep Tech Business Model Competition Winners [NIT, India 2021]

Vale's Business Competition Finalists [Mining Hub 2022]

Granted multiple global patents in robotic construction [2022]

Industry Challenges

Outdated tools & practices resulting in chronic disorders and worksite injuries to workers while offering the least protection.

A shrinking talent pool with 25-40% of skilled, aging workforce planning to retire by 2030, and few takers among millennials

Capital constrained Industry with unmitigated operational risks and razor thin margins resulting in amongst highest number of insolvencies

3 Billion Tonnes of annual construction waste responsible for 10% of global waste, due to 1/3 of total building material wasted

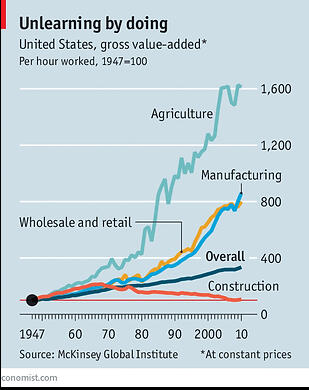

Lowest workforce productivity (gross value added in terms of output per hour worked remaining at a standstill since 1945)

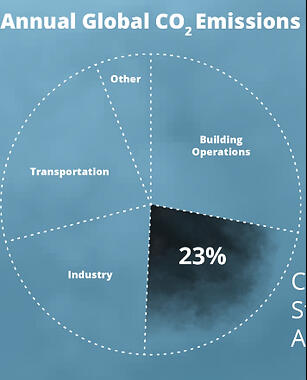

High Carbon Footprint Concrete, steel, and aluminum – are responsible for 23% of total global emissions (most used in built environment)

Collaborative Robotic Mason Demo

Semi-automated collaborative robotic mason to accelerate block laying activities in building construction.

Robotic Masonry

Concept Note

Robotic Masonry

Early Prototype

Patents

General Systems has won three international patents in application of robotics to the Construction space. Please reach out for more details.

Our commitment to a Sustainable Construction Industry

We believe that sustainable and affordable infrastructure development is key to building inclusive societies, and we are committed to addressing construction sector’s challenges around high worker injuries, high material wastage and enabling the Industry's business sustainability.

#1 Reducing Carbon Emissions

UN SDG CHALLENGE

Building and construction are responsible for 39% of all carbon emissions in the world

SOLUTION APPROACH

We support construction with greener alternatives such as AAC, FlyAsh Blocks Vs traditional concrete, and use of Epoxy vs Mortar.Resulting building structures offer 4x savings in CO2 emissions that is almost 22.4 MT of CO2 per 1000SqFt of Apartment building, and upto 10x improved thermal efficiency, in addition to significant cost savings in construction materials.

UN SDG CHALLENGE

Enormous gender gap, unconscious gender bias, only 11% of Construction workers are women, and a mere 1.4% in actual production

SOLUTION APPROACH

Our robotic machines de-couple heavy lifting & repetitive hard labour masonry activities (block lifting, placing) from skill based activities, effectively breaking gender barrier to employing women masons. In addition by offering machine operator role, masons could command better pay grades and growth.

#2 Breaking Gender Barriers

#3 Avoiding Onsite Injuries

UN SDG CHALLENGE

Construction sector today has amongst the lowest worker productivity (GVA/Hr worked) at one end, and highest rate of workplace injuries at the other. Masons in particular are amongst the most impacted with back pain, wrist & elbows, musculoskeletal disorders etc.

SOLUTION APPROACH

Our robotic machines can handle heavy blockwork with dexterity, manage hi-rise construction and help avoid human over exposure to bad weather. Led by multi-layer operational safety checks, backed by sensor arrays and operated by skilled staff, our machines protect masons from debilitating heavy lifting of material and dangerous practices like scaffolding, resulting in drastic injury avoidance.

UN SDG CHALLENGE

Construction & Demolition waste contributes to 3B Tonnes of waste annually in 2012... 30% of total weight of building material delivered to site is wasted, and 33% of this waste comes from bricks, blocks and mortar.

SOLUTION APPROACH

We promote use of greener construction materials like Flyash, AAC blocks which enable 30% less environmental waste traditional concrete. By sensor backed handling of building materials we further maximize material utilization by 10-15%.

#4 Avoiding Construction Waste

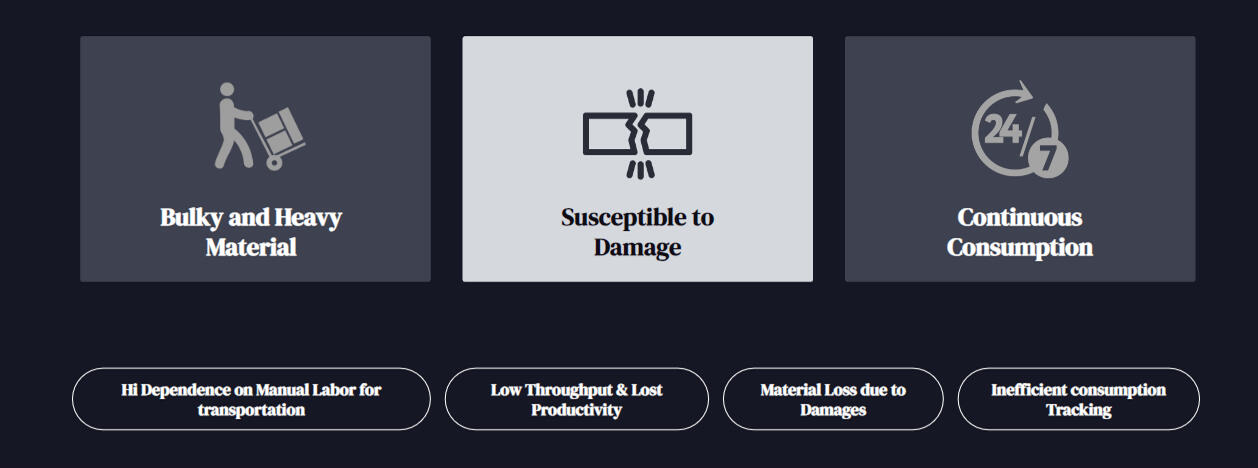

On-site Transportation of Construction materials

On-site material movement is a problem for building contractors

Our Solution Approach

Purpose Crafted vehicle navigates ramps & rough terrain

Carries 6-8x more load per trip than human workers

Zero Turn Navigation, Safe,

Hi Performance Guided vehicle

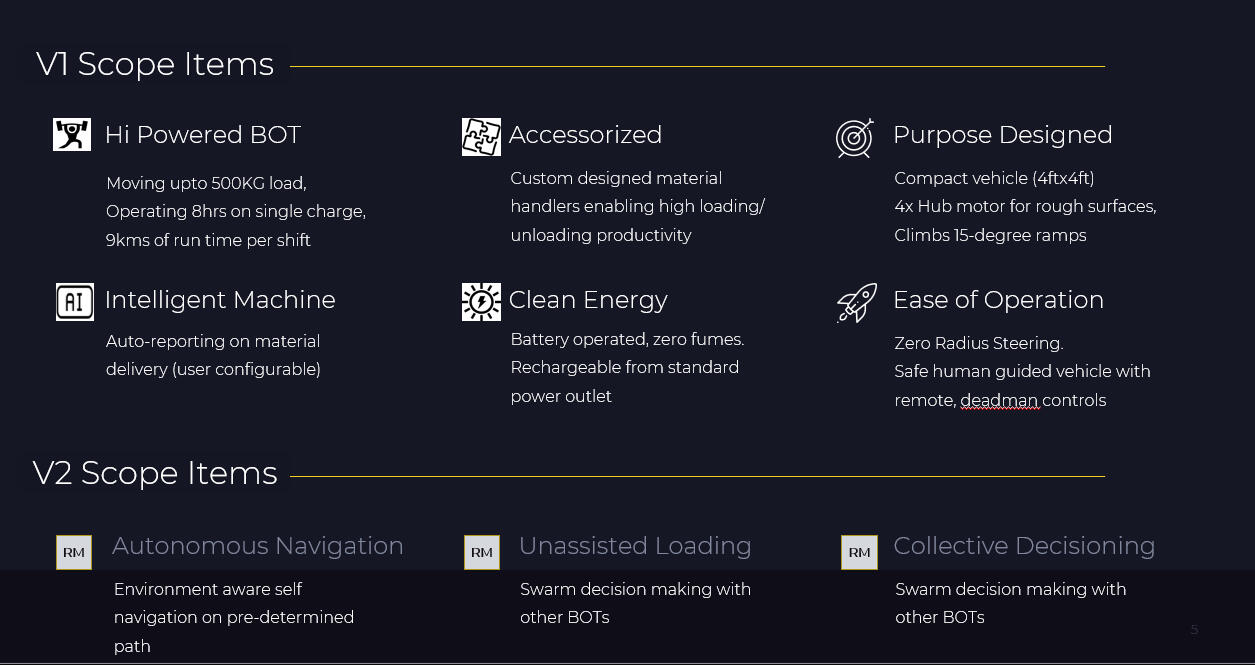

Product Roadmap

Motorized Retractable Covers for Transport Wagons

We offer an on-train mechanization solution (referred to as the Bolt-On-Kit, BOK) that automates the covering of all carriage wagons post loading, and the uncovering prior to unloading, without any human intervention.

Automated

Does not require any heavy machinery or human intervention

Green

Uses reusable, zero residue, screen to protect cargo from external rain

Rugged

Solution designed with industrial grade reliability at component level

Modular

Modular Plug-n-Play robotic component (Bolt-On-Kit) for easy service & maintenance

Zero Cloud

Localised solution with limited dependency on 3G/4G/Cloud connectivity during the journey

Deep Data

Rich analytics on a range of operational metrics (cycle time, loading/unloading time, maintenance hop time)

Founder Profile

Mukund NAMBIRAJAN

With a solid background in both business (MBA from INSEAD) and technology (Masters from the Indian Institute of Information Technology), the core skills I bring to the table:

• Cross Functional leadership: Own and lead business aspects (Business model, GTM strategy, Pricing, Client acquisition), Fundraising (investor engagements), Product (Product strategy, Product Market Fit) and People (talent nurturing, culture, policy and practices, ethos).

• Stakeholder management: Engage and manage expectations across both internal (Leadership team, Board) and external stakeholders (clients, partners, future investors).

• Operational Frameworks: Overcome ground level operational challenges by implementing

new frameworks, driving process improvements, leveraging automation, and introducing innovative point solutions

Contact Us

Please drop our founders a note and we will get back to you.

Thank You

Thanks for reaching out to us, we will get back to you ASAP!